Sustainable Manufacturing is the Next Green Initiative (INFOGRAPHIC)

Brian Wallace, Founder & President, NowSourcing

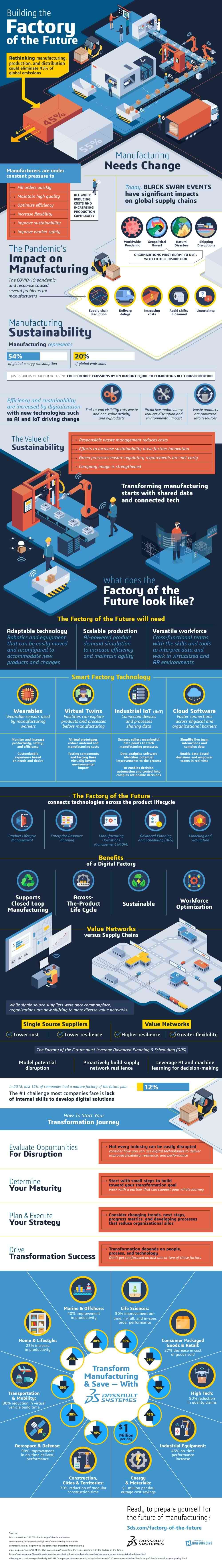

Before the COVID pandemic, most industries across the globe were already concerned with making changes to their processes to become more sustainable and environmentally friendly. The manufacturing industry was naturally gearing toward these changes as well, but as with the vast majority of anything and everything in need of major updates, the COVID pandemic highlighted all the foundational cracks and caused efforts to switch into high gear.

It was already evident that the manufacturing industry needed substantial shifts toward green initiatives, as manufacturing is currently responsible for 54% of energy usage and 20% of emissions, worldwide. However, through the lens of the pandemic, we also see that the manufacturing industry has to take a sharp turn toward the future when it comes to planning for unforeseen disasters as well.

Beyond the event of a pandemic, other “black swan” events such as geopolitical unrest, natural disasters, and shipping disruptions can have the same kinds of devastating effects on the manufacturing industry that we experienced particularly during the height of the pandemic. As with the pandemic, these effects can look like supply chain disruptions, delivery delays, rapid shifts in demand, uncertainty, and increasing costs.

Even without unforeseen events and the need for greater sustainability, manufacturing managers are in a constant balancing act to get things done efficiently, quickly, and with the highest quality. They have to maintain safety and flexibility and are under enormous pressure to continue reducing costs and increasing production complexity.

These all may seem like impossible goals to achieve, especially in addition to thinking ahead for future “black swan” events and making the manufacturing industry “green friendly”, but there are actual solutions that can resolve all of these issues combined. For instance, making changes to just 5 areas of manufacturing can reduce emissions at a rate equal to the amount of removing all forms of modern transportation. These changes completely eliminate 45% of global emissions.

Manufacturers can make huge strides in sustainability and efficiency by using new AI and IoT technologies. These technologies can create end-to-end visibility to cut waste, predictive maintenance to cut down on disruptions and environmental impacts, and can help manufacturers to reuse waste products as resources rather than simply throwing them out.

The factory of the future is one that is built on digital technologies. These technologies are connected across the entire lifecycle of the product and they include product lifecycle management, resource planning, manufacturing operations management, advanced planning and scheduling, and modeling and simulation. Every process is easily connected and visible at all times.

Technologies like wearables for factory workers, virtual twins, industrial IoT, and cloud software will also benefit these digital factories, helping them to be more sustainable and to optimize their workforce. Making the change to sustainability will not only benefit the world, but will also be the catalyst for more innovation, reduce waste management costs, and give a positive boost to company image.

The manufacturing industry of the future could make significant positive impacts on the environment and could lead the way for innovation, helping other industries to make these long awaited changes as well.

About the Author: Brian Wallace is the Founder and President of

NowSourcing, an industry leading infographic design agency in Louisville, KY and Cincinnati, OH which works with companies ranging from startups to Fortune 500s. Brian runs #LinkedInLocal events, hosts the Next Action Podcast, and has been named a Google Small Business Adviser for 2016-present. Follow Brian Wallace on Linked

About the Author: Brian Wallace is the Founder and President of

NowSourcing, an industry leading infographic design agency in Louisville, KY and Cincinnati, OH which works with companies ranging from startups to Fortune 500s. Brian runs #LinkedInLocal events, hosts the Next Action Podcast, and has been named a Google Small Business Adviser for 2016-present. Follow Brian Wallace on Linked